For manufacturers evaluating advanced machining equipment, the investment return is always a core decision driver. DUOMI CNC drilling and milling machines don't just deliver precision—they also deliver clear financial benefits, increased productivity, and long-term cost savings for industrial operations of all sizes.

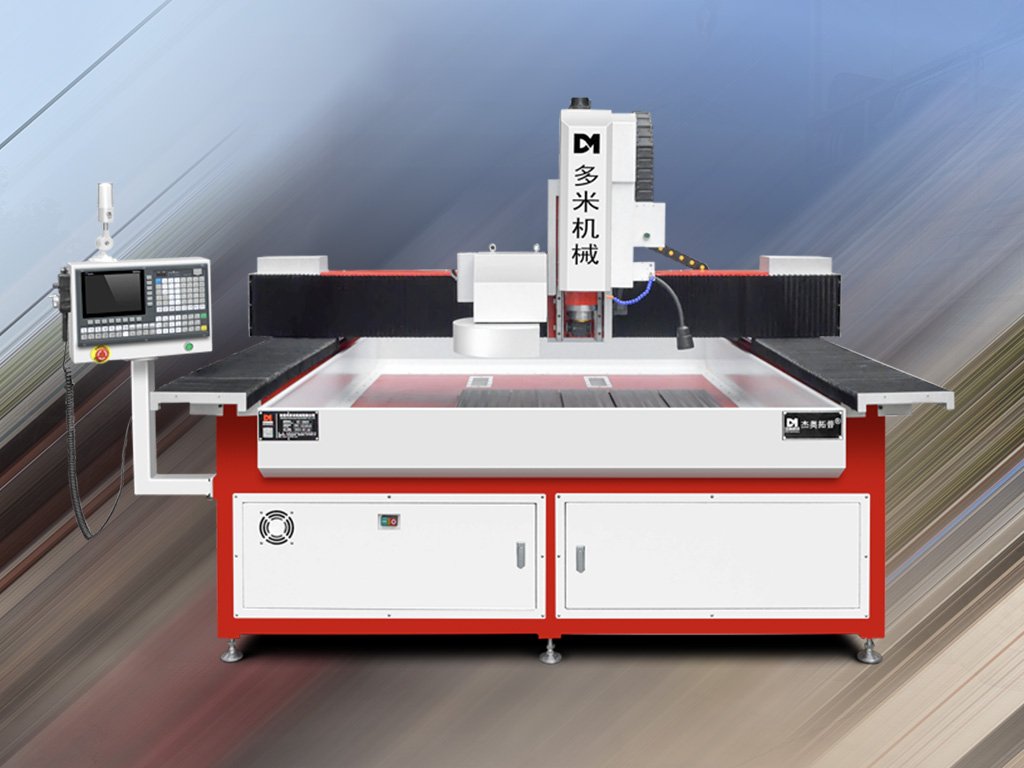

CNC drilling and milling machines

Reduced Production Cost Through Precision and Automation

One of the most significant ways DUOMI CNC equipment delivers value is by automating complex drilling and milling tasks. By replacing manual operations with CNC control, errors due to human fatigue and variability are minimized. This leads to lower rework rates and reduced scrap material, directly translating into cost savings over time.

Precision machining also means more consistent parts with fewer defects. Parts that match tolerance requirements the first time eliminate costly quality control cycles and customer returns—an important factor in industries where quality is non-negotiable.

Increased Throughput and Shorter Lead Times

Investing in a DUOMI CNC drilling and milling machine means your factory can operate at higher throughput levels. These machines run consistently with automated tool paths—cutting cycle times and reducing setup times compared to traditional machining.

Faster machining and reduced idle time allow manufacturers to fulfill more orders without adding headcount or additional equipment. This improvement in capacity utilization directly boosts revenue potential and shortens the time it takes to recoup the initial investment.

Versatility Across Materials and Applications

Unlike equipment designed for a single task, DUOMI CNC drilling and milling machines can handle:

Drilling, milling, and tapping processes

A wide range of materials like aluminum, carbon steel, and stainless steel

Variable part sizes and complex geometries

Such flexibility means a single machine can replace multiple specialized tools, lowering capital expenditures and shop floor footprint. As a result, manufacturers can pivot between jobs without purchasing separate equipment—improving ROI by maximizing machine use.

Long-Term Operational Savings

Although initial capital expenditure is an important consideration, the total cost of ownership (TCO) paints a clearer picture of value. DUOMI CNC machines are designed with durability, predictive maintenance capabilities, and optimized programming support, all of which help reduce downtime and prolong machine life.

Reduced downtime keeps production lines active, while maintenance alerts help avoid costly breakdowns before they occur. Minimizing unexpected repairs preserves profitability and supports long-term operational planning.

Competitive Edge Through Consistent Quality

In global markets where precision and repeatability are non-negotiable, having a CNC drilling and milling machine positions your business ahead of competitors. High quality, repeatable parts differentiate your products and brand reputation—leading to more contracts, larger clients, and higher margins.

Consistent output also supports compliance with industry standards and customer specifications, which can open doors to new partnerships in sectors like automotive, appliance, and industrial fabrication.

Tangible ROI That Multiplies Over Time

Manufacturers often see ROI through reduced labor costs, improved yield, higher throughput, and enhanced product quality. When combined, these benefits form a compounding financial advantage that extends far beyond the initial purchase price.

By automating repetitive tasks, minimizing waste, and delivering reliable performance, DUOMI CNC drilling and milling machines turn capital investment into measurable business growth.