Today we talk about the flow drilling process, that many customers ask us, 6mm can drill, 0.8mm can drill? The answer is yes. But different wall thicknesses adapt to different hole diameters, if the wall is too thin to make a big hole, it does not actually have two threads. If the wall is too thick to make holes, the length of your drill edge will determine that it only has one bushing that long.

The flow drilling process can actually be understood as the process of replacing the pressure riveted nut with a thin wall connection. Now the customer's products are riveted nuts up, we can wait for a moment to actually operate the machine tool, and then see its hot melt out of an effect, we do a comparison.

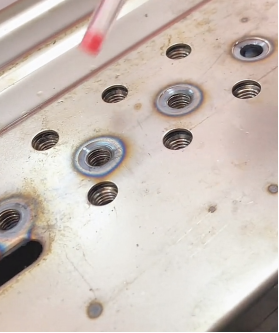

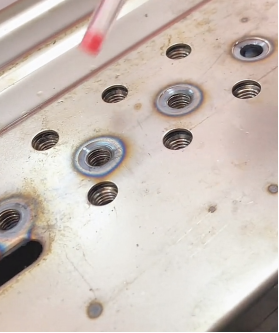

The customer's product is a 1.5 mm thick plate and 1.2 mm thick plate welded together, we test the flat mouth effect of M10, after drilling the drilling spindle will be lifted automatically, and now tap.

Now let's take a look at the surface effect of the riveted nut, this circle is the customer's riveted nut, we can see that the riveted nut, it is the two layers of the material welded together, so the top layer of it is completely without thread, thread is the nut below.

And our flow drilling made, is the top layer and the bottom layer of the thread are connected together, that is, it will be one or two more threads than this.

Then look at an effect on the opposite side of it, the effect on the opposite side is the same, this is just a nut welded here, and on this side we are also connected together as a whole, there will be a few more threads, and the screw will be stronger.

In addition to increased thread strength, our flow drilling process is then simplified. When rivet the nut, you need to punch the hole first, and then rivet the nut. Now we have this machine tool you can install on the flow drilling, and then the flow drilling tapping is completed in one, and the thread is stronger, more saving processing time.

Source of this article: http://www.duomicnc.com/