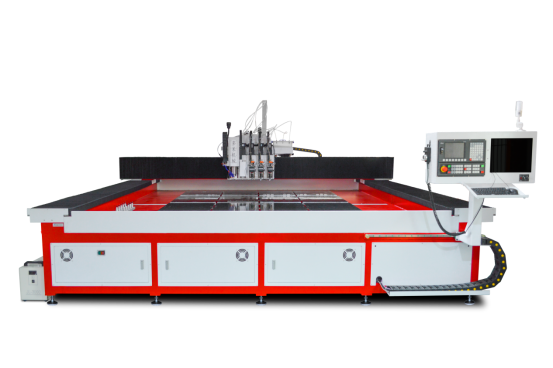

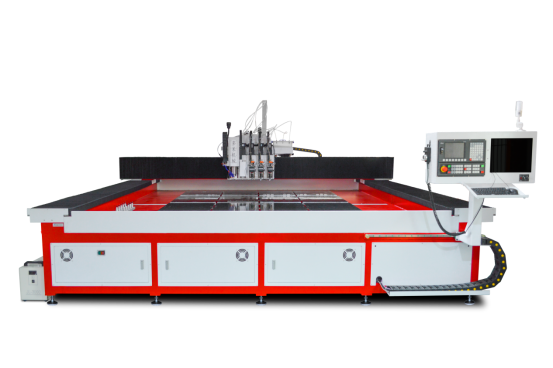

Today, let’s take a look at a CNC drilling and riveting machine customized by Xiangyang Hangyu. This is a multi-functional CNC machine tool that integrates CCD visual imaging, automatic drilling, and automatic riveting.

Because the customer's requirement is to rivet the main frame to the aluminum plate, the CCD visual imaging of the CNC drilling and riveting machine needs to automatically scan and identify the hole positions, and transmit the identified hole position imaging generation program to the CNC machining center system. , which is also preparation for subsequent automatic drilling and automatic riveting.

The automatic drilling part of the CNC drilling and riveting machine is controlled by a standard CNC machining center system. The X-axis and Y-axis are large-format working lines of 2.3m*2.8m process, the entire CNC drilling and riveting machine structure adopts a structural form of widened and heavy-weighted beam door type. The Y-axis is a dual-drive transmission, and it cooperates with heavy-duty ball linear slide rails to ensure the smooth operation of the machine tool.

The work surface of this CNC drilling and riveting machine is assembled from 16 separate steel plates after grinding, so that the overall plane accuracy is guaranteed to be within 0.05mm.

The 10-row tool magazine supports the program to automatically replace the required tools. The tool holder is connected with a strong spring between the installation plate and the locking knife plate. The error can be calibrated to a certain extent when changing tools, making tool changing convenient and stable.

Next is the automatic riveting part of the CNC drilling riveting machine, which is composed of 3 rivet guns and 3 vibration disk nail feeding boxes, corresponding to the customer's three specifications of rivets. The worker will pour the corresponding rivet into the vibration disc, the direction of the rivet will be automatically arranged by the vibration disc, and then transmitted to the muzzle of the corresponding rivet gun through the gas pipe, and then moved to the designated rivet position by the mechanical movement, the rivet gun will be automatically nailed, according to the CNC system program to complete the riveting processing.

The discarded rivet end handle part will also be directly transmitted from the rivet gun to the recycling box here, and the numerical control system part reserves a number of electromagnetic valves and data interfaces to facilitate the automatic matching of the customer's homemade fixture with the CNC drilling and riveting machine in the later period.

Source of this article: http://www.duomicnc.com/